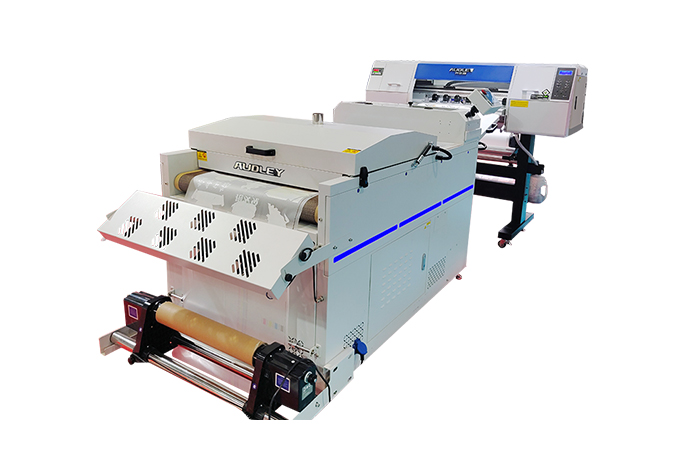

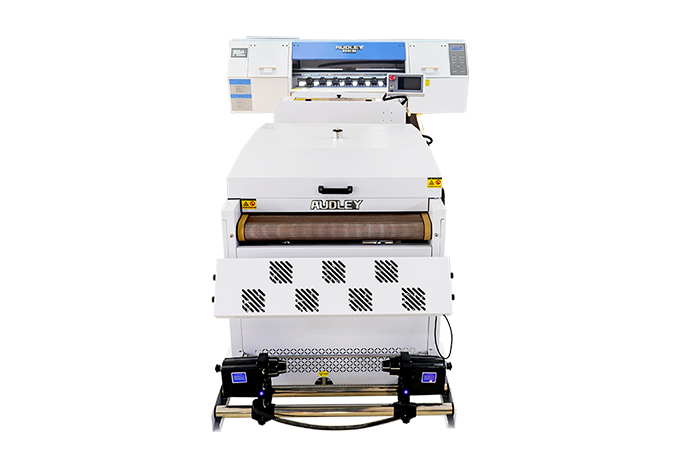

S7070-3 2 Head DTF Printer

Multi-Color Printing Capability: This machine is designed for multi-color printing, allowing users to create complex designs with ease. With the ability to print in CMYK+Cyan+Cyan+White+W, users can produce a wide range of colors and designs, making it ideal for various printing needs.

High-Quality Printing: The AUDLEY dtf printer features a high resolution of 3200 dpi/1080 dpi, ensuring crisp and clear prints with minimal ink bleeding. This makes it suitable for printing on various materials, including t-shirts, hoodies, and other apparel.

- Package Size 198*76*71cm(Printer)

- Weight 235KG(Printer)

*Warranty: 1 year, print head and ink road have no warranty

Technical Parameters

1 year, print head and ink road have no warranty

| Printer Model | S7070-3 | ||

| Print head | 2 head Epson i3200-A1 | Powder | DF-800(A) |

| shaker model | |||

| Board | Hoson board | Working width | Less than 60cm |

| Speed | 4pass:14sqm/h | Heating tube | 5PCS*805MM(800W/pcs) |

| 6pass:8sqm/h | |||

| 8pass:6sqm/h | |||

| Working size | Less than 60cm | Power | 4500W |

| Ink | Pigment ink (CMYK+White) | Packing size | 198*76*71cm(Printer) |

| 180*115*128cm(Shaker) | |||

| Voltage | 220V 50HZ/60HZ(Standard) | ||

| Working environment | Temperature:15℃-30℃ | Weight | 235KG(Printer) |

| 366KG(Shaker) | |||

| Power | 1400W | ||

Equipment Details

State-of-the-art printer built with advanced technology to offer high precision, speed, and stability to your business success.

Print Head Configuration

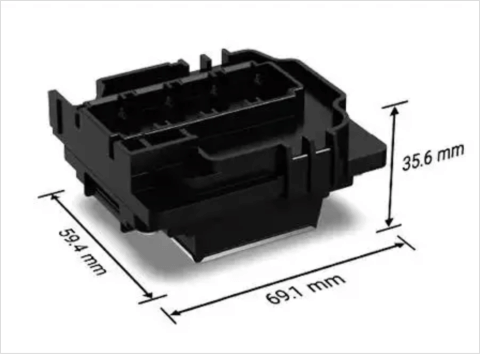

I3200 print head Parameter

DTF STAR IV Desktop A3 DTF printer using Epson I3200 print heads. Epson I3200 head has 3200 nozzles, a resolution of 600dpi, jetting frequency is higher than DX5 and xp600, and also color saturation, printing speed, and printing accuracy are better, and the price is cheap. Very cost-effective.

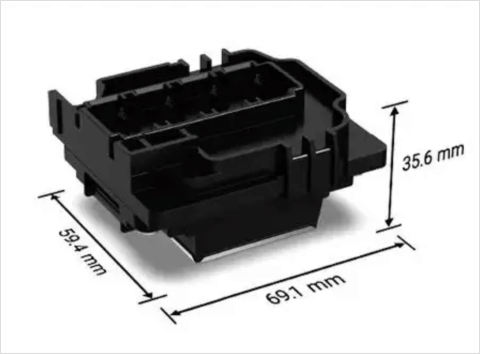

DTF Printer I3200 print head Parameter

| Model | I3200-A1 |

| Ink Types | Water based ink |

| Size(width x depth x height)(mm) | 69.1×59.4×35.6 |

| Weight(g) | 82 |

| Nozzle Numbers | 3200 |

| Length Between Nozzles(inch) | 1/300(in one row) |

| Nozzle Row | 8 row |

| Max color/head | 4 colors |

| Resolution | 300 npi/1 row 600 npi/2 rows |

| Effective Printing Width(mm) | 33.8 |

| Jet Freqency(kHz) | 43.2 (single dot), 21.6 (multi dot) |

| Ink Drops(pl) | 3.8-6-12(9.4) |

| Ink Viscosity(mPa.s) | 3~4 |

Printing Process

The DTF printer has the characteristics of fast printing speed, high color restoration,and excellent printing precision. lt is mostly used for small-batch production.lts advantages such as simple operation and relatively low cost are very suitable for entrepreneurs.

Color Channel for Design Spot

Create spot color channels using a variety of design applications.

Drawing Software RIP

Utilize RIP software; spot color and color are RIP out.

Drying While Printing And Powdering

DTF Fluorescent printing, dusting, drying, and automatic winding are all integrated processing steps.

Pressing of Garments

The printed PET film will either be manually or mechanically cut, hot pressed, and torn before being considered complete.

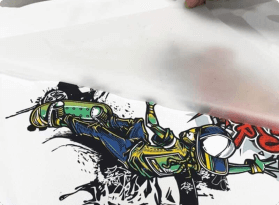

Applications

Widely used in any fabric, Tshirt, hoddies, Hats, sports dress, Leather,bag, shoes,Canvas,Mask,Socks,Glove,Acraf,Toys,Underwear, Swimsuit,Craft,Lable marking……

DTF Accessories

DTF Accessories inculding DTF textile inks, DTF shaking powder and PET Film with high quality accessories for DTF printing with affortable price.

DTF PET Films

DTF film can be transferred on a wide range of fabrics. Capable of printing to shirts, sweaters, hoodies, pullovers, canvas, denim, and more! Our DTF films have excellent ink absorption for high-precision printing. Use our film you will achieve high-quality, breathable, and smooth prints.

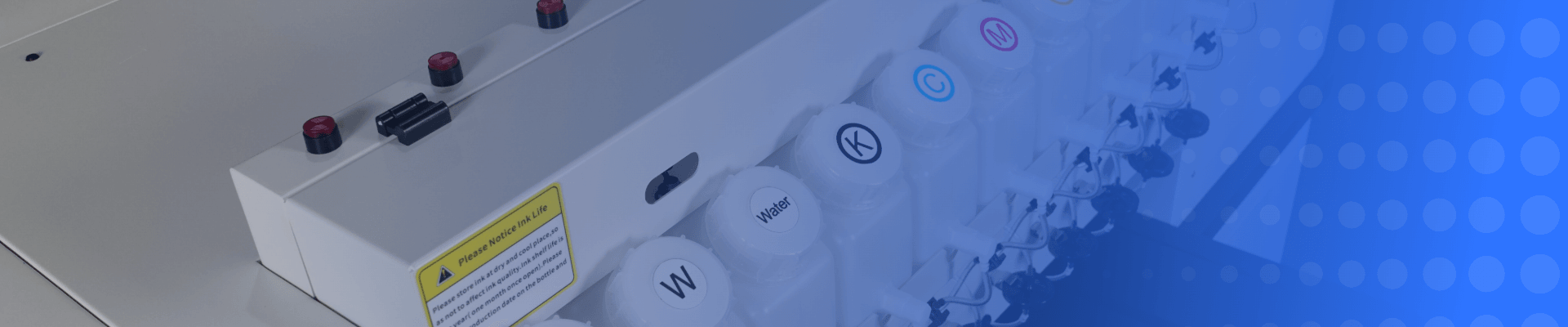

DTF Textile Printing Ink

DTF textile printing ink is highly compatible with print Epson heads. You can directly print your designs on different textiles and fabrics using Direct to Film Ink technology.ORIC offers different colors of DTF inks such as W, Y, K, M, C, Or, Gr, and also fluorescence pink & fluorescence yellow.

DTF Hot Melt Powder

Unlike DTG technology, DTF requires no pre-treatment.The most important factor is DTF Powder. DTF powders are specially designed to use with DTF printing process. Our DTF powders are slow drying and easy to cold tear. Which will help you get excellent transfer printing results.